Navigation

Contact

- +86-186-28316150

- [email protected]

- Chongzhou Industrial Development Zone, Chengdu,Sichuan, China

Know-how

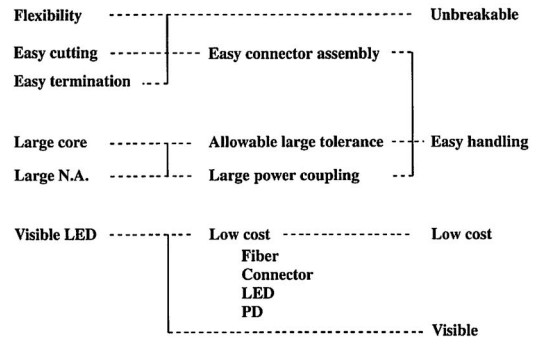

What is POF? Abbreviated as POF, polymer optical fiber(also called plastic optical fiber) is a type of optical fiber that uses Polymethylmethacrylate (PMMA) as the core material and Fluorineresin as the cladding material that allows the transmission of light. POF is often called consumer optical fiber as it is a lowcost optical fiber alternative that is easier to use than glass optical fiber. It sustains a data transfer speed of 2.5GB/s, which isn’t as fast as glass optical fiber, but is much faster than traditional copper wire.

What is step-index POF?

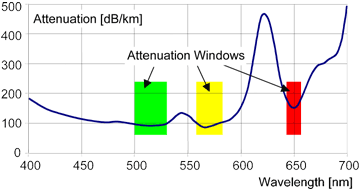

The PMMA (poly-methylmetacrylate) core is enclosed by a thin cladding (10/nbsp;µm) made from a fluorinated polymer. Through total reflection the light is guided inside the core.The lowest attenuation values occur at 520 nm (green), 560 nm (yellow) and 650 nm (red).

Differences in transit time of different rays in the core lead to a broadening of the launched light pulses. Possible bit rates are limited to about 100 Mbit/s over 100 m for SI types (correspondingly higher for shorter distances). Modified index profiles permit higher data transmission rates. The maximum operational temperature ranges from +70°C up to +85°C, depending on the application.

Applications of POF:

Polymer Optical Fiber(plastic optical fiber) are used

for Automotive(POF-MOST Cable):

- MOST (22 Mbit/s since 2001)

- Byteflight (from BMW)

- MOST2 and IEEE1394 (data rates from 150 Mbit/s to 400 Mbit/s under development)

for Data communication(pof cable for datacom):

- Ethernet (100 Mbit/s over 50 m)

- ATM (155 Mbit/s over 50 m))

- IEEE1394b (100 Mbit/s over 70 m; 400 Mbit/s over 100 m under development)

for Fiber Optic Sensors:

- Pedestrian protection

- Short curcuit and earth fault indicators

for Industrial Fiber Optic Automation(Avago HFBR patch cord):

- SERCOS (2 Mbit/s, 60 m))

- Profibus (1.5 Mbit/s, 60 m))

- INTERBUS (2 Mbit/s, 70 m))

- Fast Ethernet (100 Mbit/s, 50 m))

for Illumination(fiber optic lighting):

- Starry skies

- Luminous textiles

- Fiber optic chandeliers

- Fiber optic lighting kits

- Swimming pool lighting

- LED fiber optic lighting

- Solar fiber lighting

POF for special applications:

CMT-POF:

POF cable with Corrugated Metal Tube have increased mechanical, chemical and thermal stress tolerance, used, for example in automotive applications.

Hybrid-POF:

POF cable in combination with copper wires, utilized in tow-chains.

POF cable for High Temperature:

POF made of different materials (for example polycarbonate, elastomere, cross-linked PMMA) could in principle be used for temperatures up to 145°C.

POF cable for consumer electronics:

Toslink Cables – Digital Audio Optical Cables for Home Theater Surround Sound connection.

Back to homepage